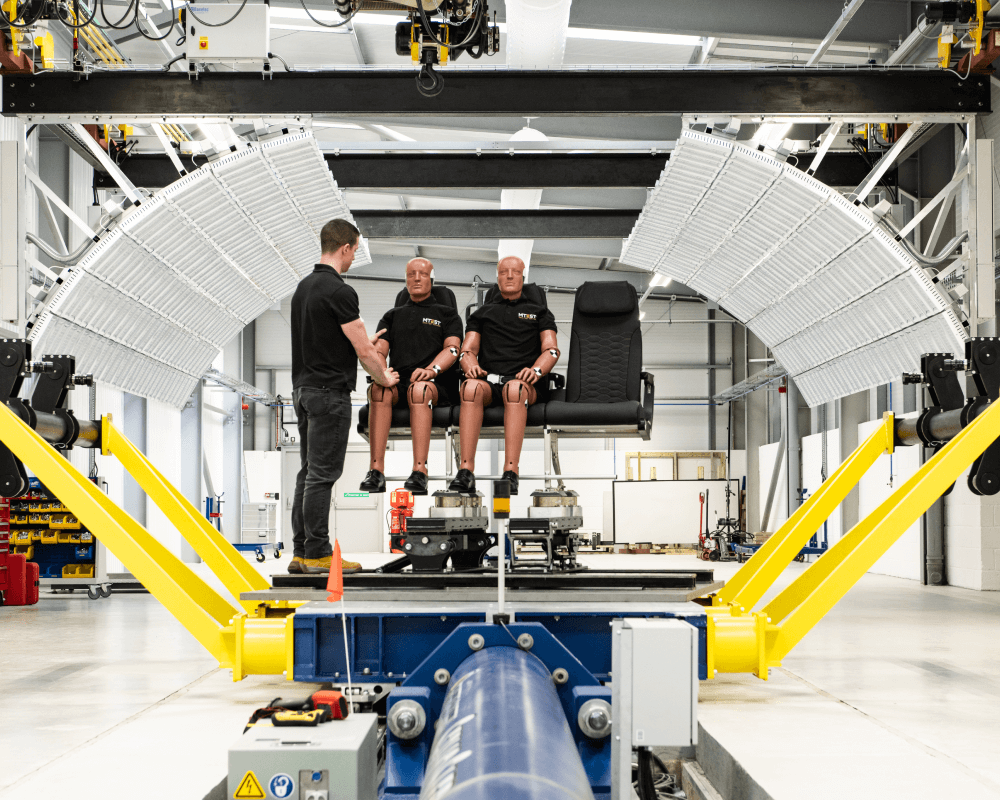

Our M-TEST facility opened in 2023 and marked a key milestone in Mirus’ growth trajectory.

The state of the art 407m² dynamic testing facility is located on the same site as our existing 3,800m² Mirus Aircraft Seating head office building in Hingham, Norfolk.

This UKAS ISO 17025 accredited laboratory features the latest in aircraft testing technology and is the largest commercially available dynamic testing facility in the UK.

Aviation

ATD’s

3x Fully instrumented HII ATD’s – In house

FAA HIII Fully instrumented ATD – Available on request

Instrumentation

6 x Floor interface load cells

4 x Seat belt load cells

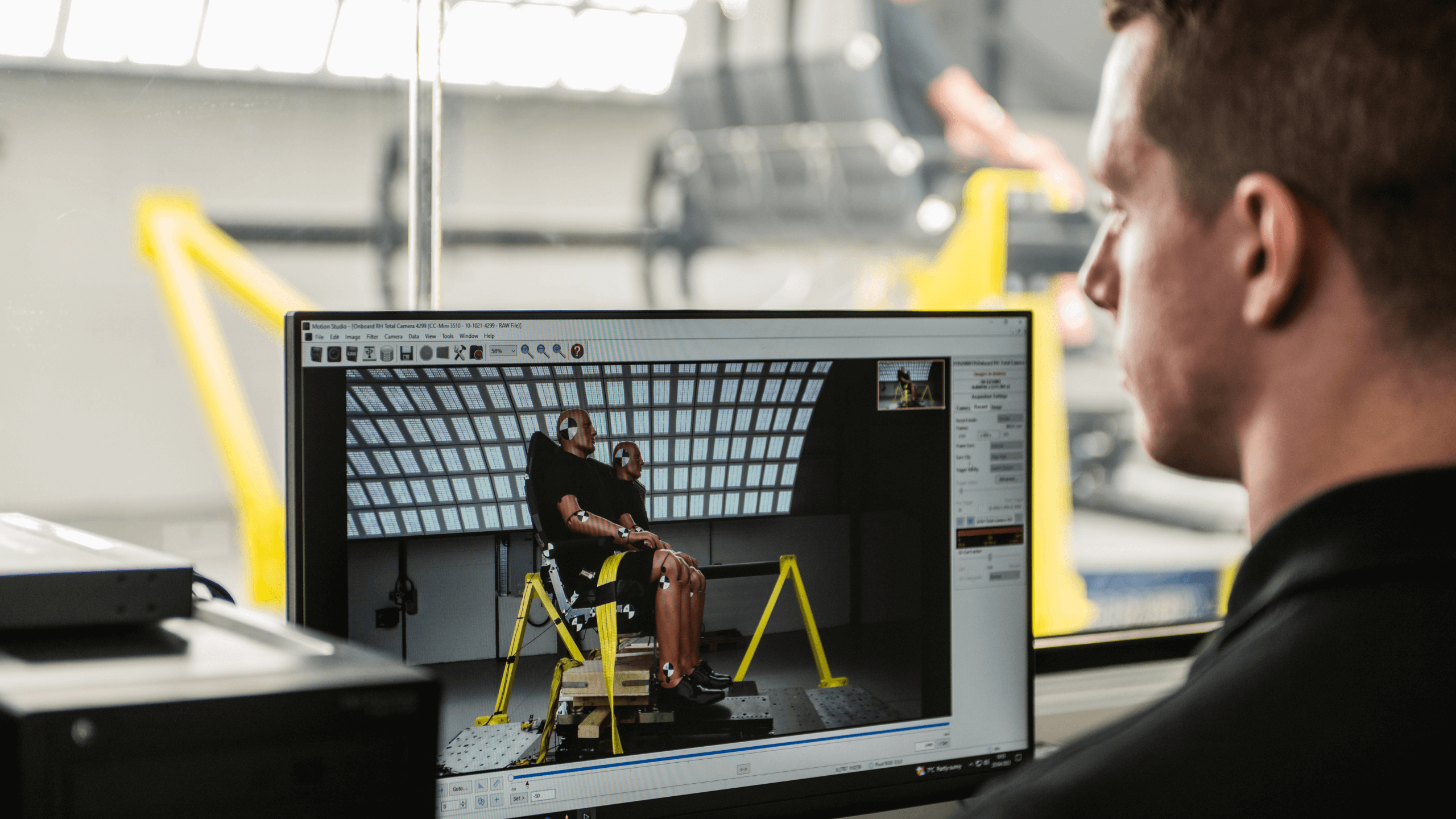

Video

Up to 8x high speed cameras (1000fps)

IDT CCM-3510 High speed cameras with tracking software

Onboard & offboard filming capability

Testing Capability

Custom-made made fixtures

SAE AS8049D Structural pitch & roll test

SAE AS8049D Structural down test

SAE AS8049D Occupant injury (HIC) test

Automative

Data acquisition

72 data channels

18 digital events

4 Fired devices

Video

Up to 8x high speed cameras (1000fps)

ATD’s

Fully instrumented HII ATD’s – In house

H-Point manikin + HRMD – In house

Fully instrumented HIII ATD’s – Available on request

Child ATD’s – Available on request

Testing Capability

Frontal impact crash simulation testing

BS EN1789:2020 – 10g Ambulance testing

ISO 7176-19 – Wheeled Mobility Devices for use as Seats in Motor Vehicles

ECE R17 – Dynamic seat strength & luggage retention

Dynamic Test Facility Specification

Seattle Safety 2.0MN ServoSledSystem

Nominal Force:2000kN

Max Velocity: 90kph (56mph)

Max Acceleration: 104g

Maximum Jerk Rate: 20g/ms

Max Payload: 3000kg

Sled Top Plate Dimensions: 3.5m x 1.5m

More accessible advancements.

Taking ownership over our dynamic testing operations is about speed and agility. It ensures we can get certified products to market as quickly and effectively as possible — both in terms of new product developments to advance airline performance, and in helping airlines to achieve solutions more tailored to their own operations.

The time, cost and carbon footprint that is reduced by having our M-TEST facility onsite has shifted our operation into the future — leaving the wasted resources of shipping seats around the UK or overseas for testing firmly in the past. Our facilities provide not only major benefits to our internal Mirus team, but to our customers, industry and the planet as a whole.

World-class testing with a local perspective

The dynamic test facility provides Mirus the capacity to certify new products for airworthiness, without ever leaving the factory.

Innovation and agility

Mirus Test Services gives us the ability to dramatically reduce programme lead times, increase our technical knowledge, strengthen our overall competence and gives the assurance and confidence to all our existing customers and OEM's that we can take on the most complex technical programmes. Our in-house dynamic testing capability means greater opportunities for product advancement.

Sustainability

Research, development and innovation allow for weight reduction and a reduced carbon footprint for our clients. Alongside this, our on-site dynamic testing results in a dramatic reduction in shipping and travel to overseas facilities; reducing energy outputs exponentially across Mirus’ operation.

A more immediate impact.

Our promise to safely secure your data.

While our facilities are close in proximity, our unmatched confidentiality guarantees privacy both on and off site for all clients.

Facility access

The M-TEST Facility is affixed to the existing Mirus Aircraft Seating building. A Paxton door lock system restricts movement of our team between the two facilities.

Solely M-TEST team have access into the facility.

The main entrance is either through the Mirus Group reception or using the door to the front of the test facility.

All other access to the test facility has be authorised prior to visiting.

Servers and data control

All customer information is confidential and will not be stored on removable media unless it is appropriately encrypted.

All confidential information and test data is stored solely within the M-TEST network and exclusively shared with the respective customer.

The M-TEST servers have a cloud-based back-up system with full disaster recovery.

Access to information on these systems can only be done so by the M-TEST team.

The transfer of test data will be shared directly and only with the customer, no other party will have access to, or see this privileged information.

Come on a journey with us...

Please enter your details to download resources

© 2024 Mirus Aircraft Seating