High Performance Production

Date: 18th December 2017

It is one thing to design a game-changing product, but it is another thing entirely to deliver it in a lean, reliable, repeatable and sustainable manner.

Context

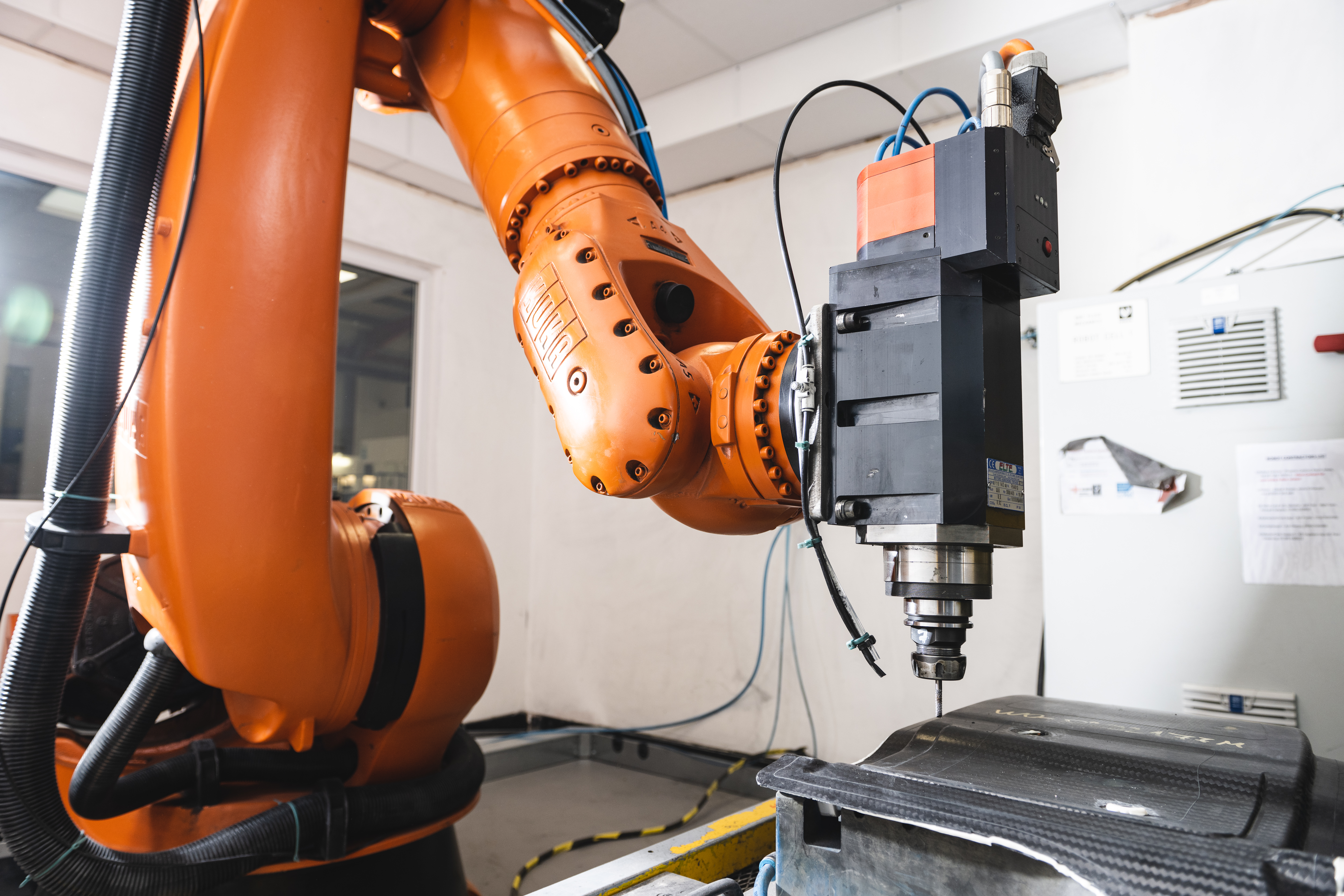

The Mirus production system is state of the art and intertwined with a ground up approach to quality systems and supply chain management. We adopt approaches and tools from the automotive industry to ensure industrial robustness, repeatability and reliability. Our ultra-efficient system is geared for high-volume mass production, a first for the aircraft interiors industry.

Mass production is an incredibly complex technical challenge. The automotive industry has pioneered and continues at the forefront of the efficient manufacture of complex products. In the automotive world, it is well known that Ford created a manufacturing revolution with the moving assembly line, whilst Toyota refined production methodologies. The sum-total of innovations over the past century has been the development of extremely efficient manufacturing systems that deliver maximum value with minimum waste. Different applications require different approaches however, and our challenge has been to adopt the right approaches for our product, adopting best practices and lessons learned from multiple industries.

The Mirus production system is designed for performance with the ultimate goal of ensuring industrial reliability.

Facility

All Mirus seats are manufactured within our fully-integrated 3500m2 production facility located in Norfolk, UK. The facility features an ultra-efficient automotive production cell manufacturing system with state of the art ERP (Enterprise Resource Planning) system and cloud-based production control. The facility has capacity for 60,000 PAX per annum.

Our facility is well versed in seeing products that extract every ounce of performance in order to excel for their given purpose. This site has a strong motorsport heritage, having been home to teams including Percival Hodges F1 Powerboats, Intersport, TOMs (Toyota Motorsport) and RTN (Racing Technology Norfolk – a wholly owned subsidiary of Audi). The site has produced numerous Formula 3, BTCC, Group-C, Formula 1 and Le Mans Prototypes (including the Le Mans winning Bentley Speed 8) and the roots of Audi’s highly successful LMP-1 campaign can be traced back to this facility (13x Le Mans wins). We are proud to be taking this facility forward, building upon this rich history. However, the challenge in building low-volume racing cars is entirely different to mass-production.

Our Approach

Our strong heritage within the automotive industry enables us to adopt best practices and introduce a new way of manufacturing aircraft seats.

We utilise the latest production methodologies, software and controls to ensure efficiency, industrial reliability, speed and scalability. We operate a lean 5S manufacturing philosophy coupled with a cell-based production system, and at the core of our operation is our holistic, fully-integrated cloud-based ERP system. This ensures total traceability, efficiency and transparency. Key elements of our approach:

- An automotive mindset– Our approach is pure automotive and we adopt a lean 5S manufacturing philosophy based around organisation, efficiency and continuous improvement.

- Systems thinking– The Mirus manufacturing process begins at the design stage and we employ systems thinking, whereby design work with manufacture (DFM / DFA) to ensure manufacturability.

- Modular product design– With maximised usage of common parts to enable high volume processes and economies of scale.

- High volume processes– enable us to manufacture high quality components more quickly and ensure the competitive pricing of our seats. Components of our current Hawk seat are all manufactured in highly tooled, high volume processes to ensure reliability, speed and repeatability. Some facts: at component level, 1 Injection molded arm is produced every 10 seconds, 1 injection molded aluminium leg is produced every minute and a carbon fibre frame is produced every 10 minutes. At final assembly level, at full capacity in our existing facility, we manufacture 15 seats every hour.

- A cellular approach– Our current facility contains a number of production cells where final assembly takes place. This approach also ensures that we are optimised for scalability and volume. Specialisation within production areas ensures optimised operator performance.

- One piece flow– is implemented (one work piece at a time between operations within a work cell) to maintain traceability and quality, no cross-contamination and elimination of waste.

- Traceability and control– We use fully integrated cloud-based systems as used by automotive OEMs. These systems control all our activities from planning through to assembly and enable live data to be accessible anywhere in the world.

- Right first time– We are committed to getting things right first time to minimise rework and waste.

Team & Philosophy

Our operations team bring years of automotive OEM / tier 1 experience to ensure a lean approach and best practice. We are committed to quality and continuous improvement and adopt appropriate automotive philosophies to ensure repeatability and elimination of waste.

Our manufacturing process is underpinned by a culture of continuous improvement and we continue to optimise this process as opportunities become available through techniques including:

- Process optimisation(utilising philosophies such as 5S, Poke Yoke, Kaizen)

- Root cause analysis(utilising philosophies such as Ishikawa, 5 Whys)

- Operator involvement

Process Control

We employ the latest automated process control technology, as used by leading automotive OEMs, to ensure error-proofing, control and total traceability. Key elements:

- Process design– Every step of our assembly process has been methodically constructed.

- Process flow– In terms of manufacture itself, line balancing has been performed to ensure optimal workshare and process flow. Combined with extensive training of workforce, defined works instructions and Pivotware software, we can ensure right first time, repeatability and a positive working environment. Our production systems ensure tight control over tolerances and tools can be finely controlled to ensure absolute precision.

- Process control– Cloud based Pivotware process control system as used by automotive OEMs. This system ensures control, quality, repeatability and mistake-proofing (Poke Yoke).

- Process improvement– through 6 Sigma techniques and tools.

- Picking process– ERP-controlled picking process. All warehouse movements are barcoded to avoid errors (inspired by leading online retailers).

Supply Chain & Control

Mirus utilises automotive quality assurance tools, software and methodologies that have been tailored for aerospace specific requirements. Mirus has adopted an automotive approach to outsourcing and has enlisted a largely automotive supply chain. Currently, 85% of our seat components are sourced in the UK. Suppliers have been nominated for industrial reliability and quality is controlled through:

- Automotive-style Parts and Process Auditsare conducted with the addition of Aerospace specific requirements. This robust process sees the auditing of all areas of suppliers in depth, both pre and post production supply.

- Advanced Product Quality Planning (APQP)process is implemented on key components. This enables product quality to improve and ensures that our requirements are satisfied.

- Product Part Approval Process (PPAP)has been introduced on key parts. FAI gives confidence regarding the sample whilst PPAP gives confidence in future products.

Mirus ensures a proactive approach to inspection and quality sign-off. Quality assurance is monitored upstream at supplier level which ensures that stock received is right first time. This preventative and proactive approach to minimising errors eliminates any issues before goods are received. This pre-empting of potential issues and working with suppliers to continuously improve minimises any issues during assembly and eases downstream internal inspection processes.

What does all this mean?

Ultimately, this means that Mirus is able to deliver seats in a rapid, efficient and sustainable manner. The ultimate goal is to deliver seats in a high volume manner that is industrially reliable and repeatable. Key benefits:

- Quality and repeatability

- Reduced cost

- Improved speed to market

- Lower carbon footprint

- Transparency

Our commitment to efficient, effective manufacture means that we are able to deliver exceptional products in a lean, reliable, repeatable and sustainable manner.

Find out more about our environmental innovation in an upcoming insight!