Founded in 2015, Mirus Aircraft Seating has grown rapidly to become a global leader in the manufacture of aircraft seating with operations in the UK, Malaysia and China. We seek excellence at every step, from conception to delivery and beyond. Come on a journey with us…

In-flight comfort grounded in innovation.

Seeking excellence at every step with ingenuity at our core. A business geared to reach new heights with every year that passes, our once-local operation now spans a significant international reach — with Mirus Aircraft Seating products enhancing the flight experience of the world’s largest operators.

“After considering various seating options for our A321 aircraft, we opted for the Hawk – we were impressed by the sleek design, low weight and the attention to detail shown by Mirus when it came to our specific requirements. We are looking forward to receiving the first shipment of seats this month, and to hearing our customer’s feedback once they are in service.”

Alexandr Pilipciuc, Technical Director FlyOne

“We considered many seating options for the retrofits of our 737-800 fleet. We were very impressed with the Hawk as a suitable product and the superior level of customer support offered by Mirus. Once retrofitted, the Hawk will significantly enhance the appearance of our cabins and offer our passengers a class-leading experience in terms of comfort and living space.”

Ronald Casso, General Manager Boliviana de Aviación

“Working together with Mirus, we are ensuring that our Boeing 767’s will fly with a state-of-the-art interior and bring our guests comfortably to sunshine destinations across Asia and the Americas."

Geert Somers, Director of Engineering & Maintenance Tui Aviation

“The Hawk not only enhances passenger experience through improved ergonomics and significantly increased living space, but also ensures an operational reduction in fuel consumption and CO2 emissions. A win-win scenario for our customers and the environment.”

Tony Fernandes, Managing Director AirAsia Group

Airbus

AerCap

Royal Jordanian

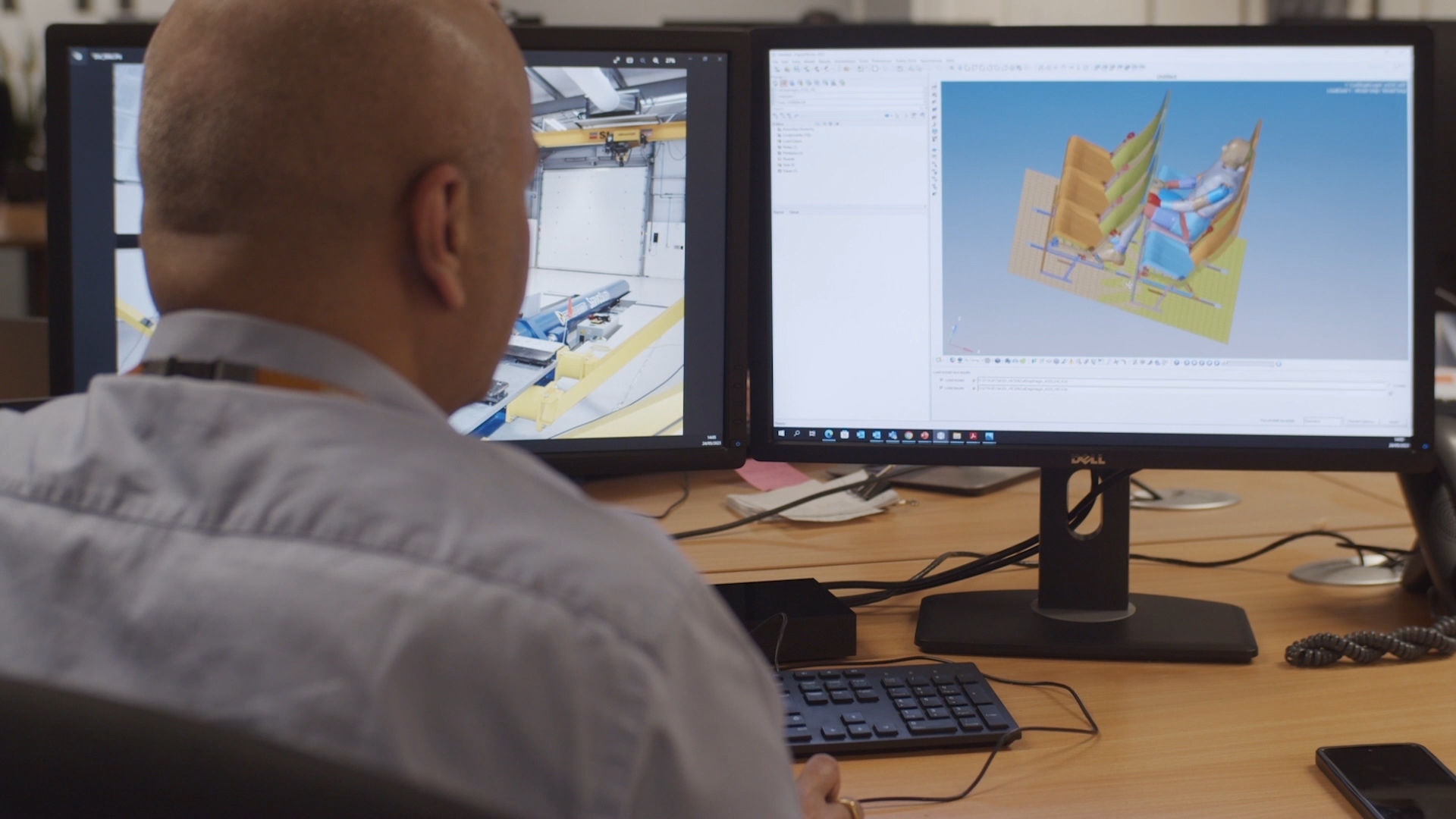

Proactivity, agility and ingenuity — this is Mirus.

Optimisation is our natural state of operation; from first interaction to your final product. Our unique approach sees a more considered aircraft seat construction at every touchpoint — ensuring your experience matches the quality of our output throughout the entirety of our partnership.

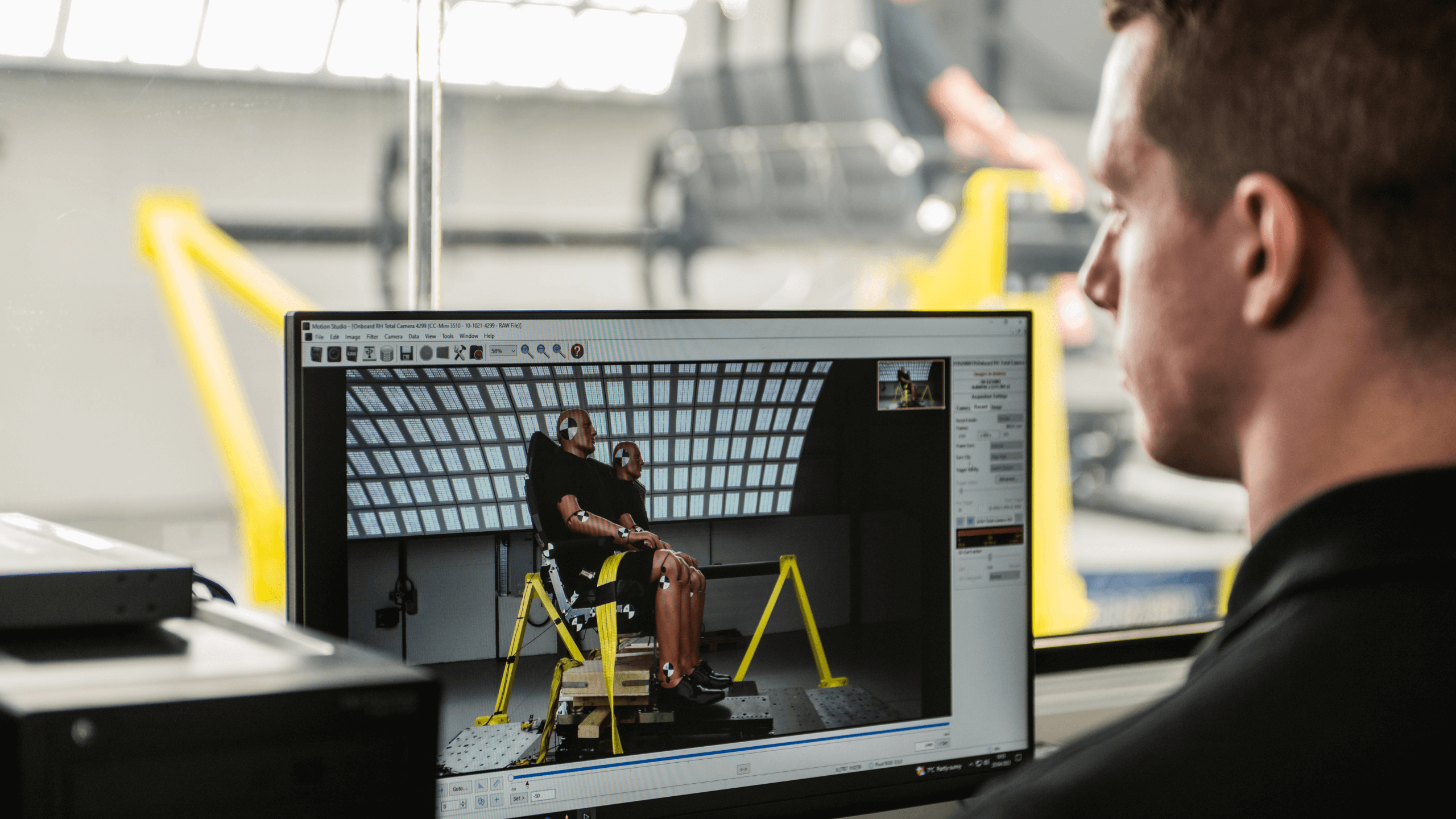

Testing limits, pushing boundaries.

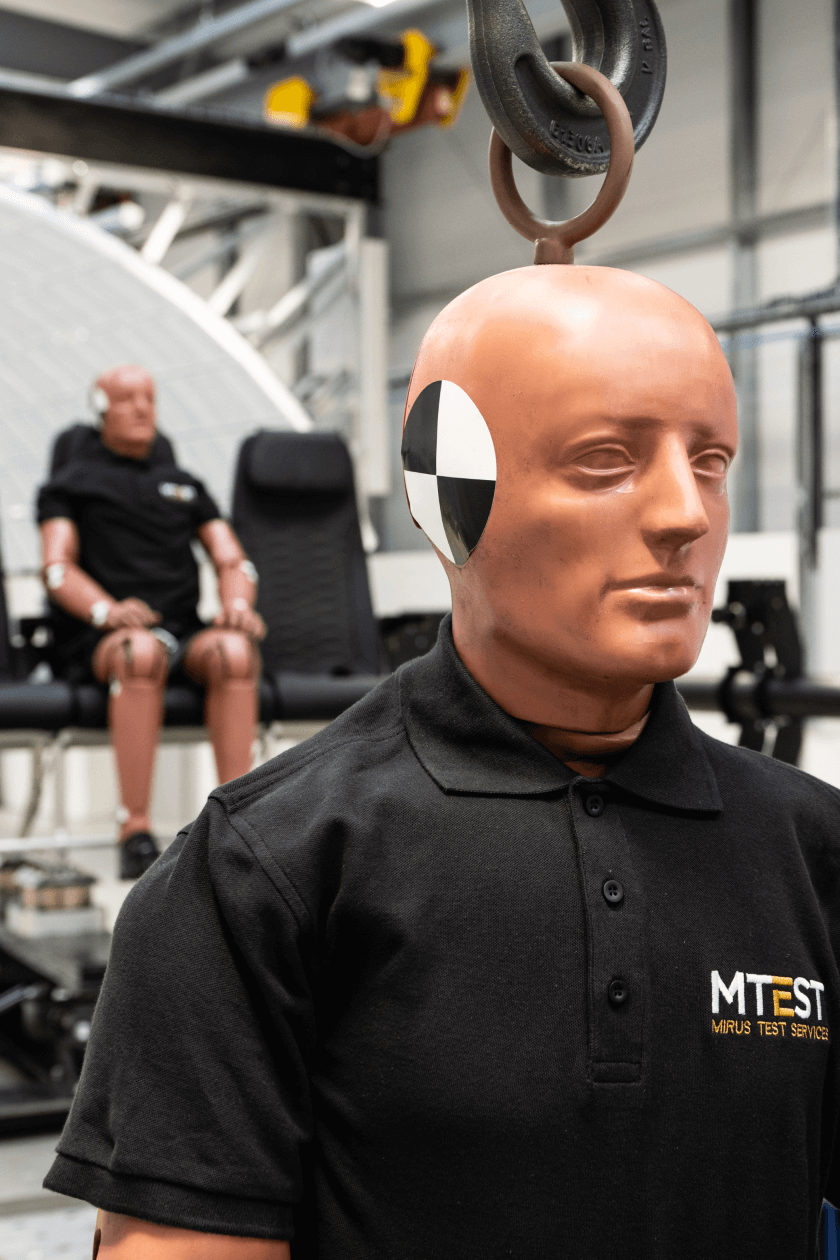

Welcome to M-TEST — the largest commercially available dynamic testing facility in the UK.

Ignite a new (flight) path.

Attuned to optimising environments — our working ones included. Join our team at Mirus and unlock your potential alongside a dedicated group fuelled by innovation.

More than the destination — it’s about the journey.

Have a question or enquiry? Our customer support team are here to help your project take flight with ease.

Come on a journey with us...

Please enter your details to download resources

© 2024 Mirus Aircraft Seating